For years, Apple staunchly defended its Lightning port, often citing its smaller size compared to the emerging USB-C standard. The difference, a mere 1.1 mm – 2.8 mm for USB-C versus 1.7 mm for Lightning – seemed a critical justification in their design philosophy.

Then came the iPhone Air, Apple’s thinnest iPhone yet, boldly featuring a USB-C port. A direct comparison reveals a startling truth: the Air’s port is remarkably slim, almost disappearing into the device’s frame. This wasn’t a simple adaptation, but a triumph of innovative manufacturing.

The secret lies in a groundbreaking process developed in collaboration with leading research institutions like TU Dresden and the Fraunhofer Institute. It involves 3D printing with titanium powder, but not in the way most would expect.

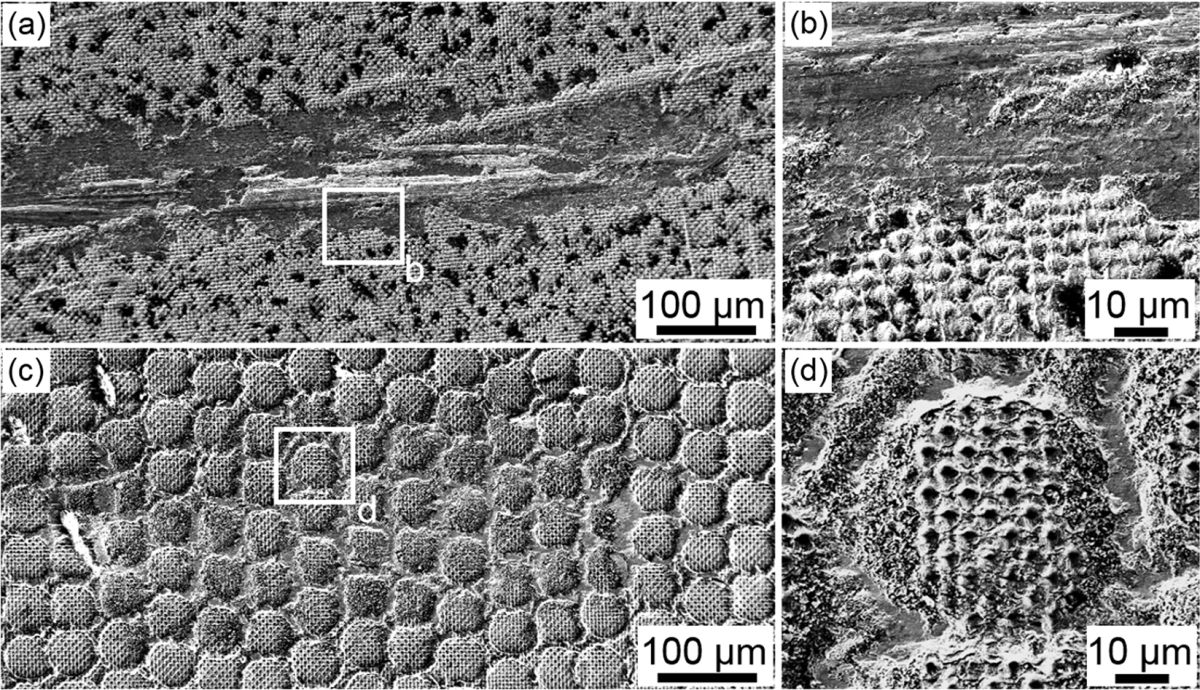

Instead of casting titanium powder with adhesives, Apple utilizes a laser-based process to mill precise molds directly from solid titanium blocks. This technique, initially conceived for advanced medical implants, creates a unique surface structure.

The original research, published in Nature, focused on creating titanium implants that integrate better with bone tissue and resist bacterial adhesion. The process generates microscopic craters and holes, enhancing biocompatibility.

While the iPhone Air’s titanium port doesn’t replicate the bacteria-repellent qualities, it inherits the material’s enhanced heat resistance. This is crucial, as the USB-C port is now responsible for charging the device.

The benefits extend beyond heat management. For the Apple Watch Ultra 3, the process has demonstrably improved water resistance. The ability to create textured surfaces, previously impossible, allows for better antenna adhesion as well.

This innovative approach isn’t just about creating smaller, more functional components; it’s remarkably efficient. Apple projects a savings of 400 metric tons of titanium this year alone, reducing raw material usage by 50 percent.

The incredibly thin USB-C port on the iPhone Air is a direct result of this advanced manufacturing technique. It’s a testament to Apple’s willingness to embrace cutting-edge technology, even those initially developed for entirely different applications.

Ultimately, this process represents a significant leap forward, demonstrating how precision engineering and material science can converge to create devices that are thinner, more durable, and more sustainable.